Pots

Loading model...

Frilly Plate

This is one of my more successful ones in that I both like how it looks and we have a good use for it. The only thing I would do differently is apply the glaze a little thinner, I applied it quite thick and it has given an incredible homogeneous surface finish, almost to the point that in real life it looks like someone printed a fake texture onto it. I would rather have the glaze show a bit more texture and variation. I particularly like the effects you get at the edges of the glaze on a piece.

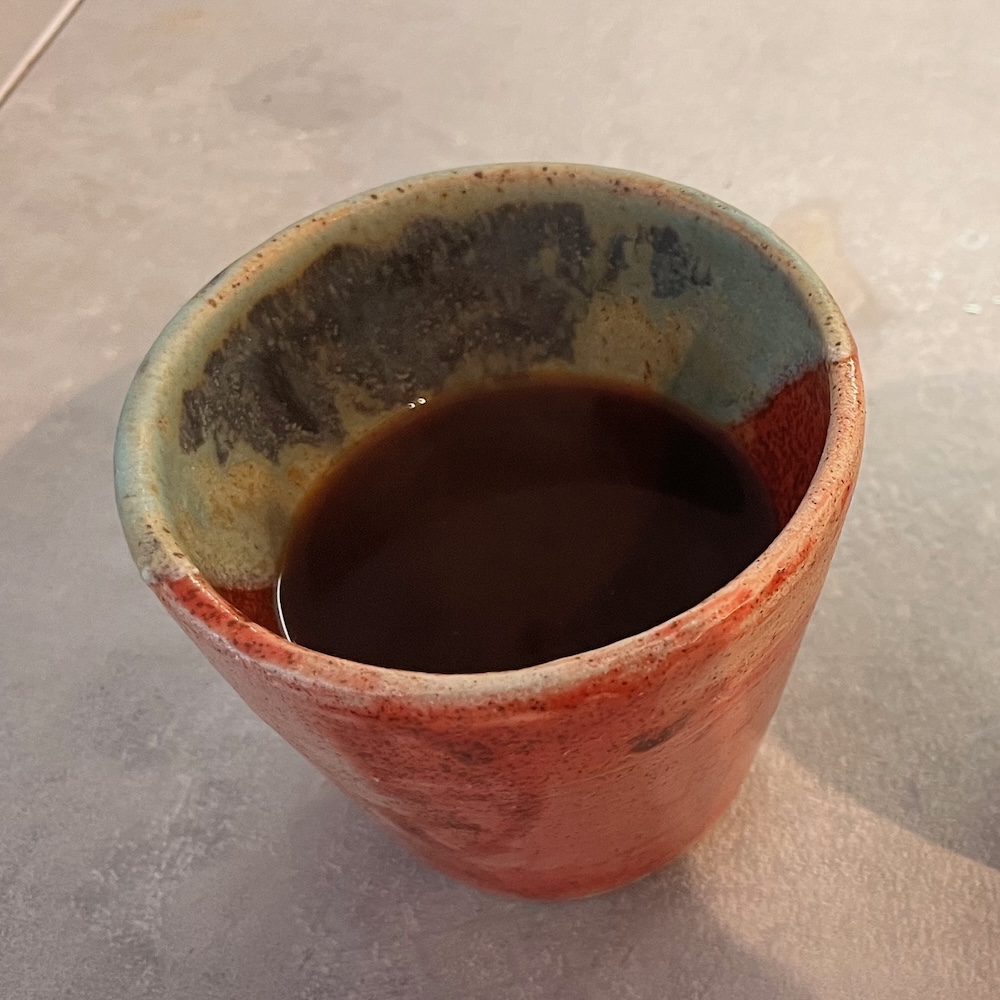

Two Tone Cup

I also like how this one came out, it’s the result of double dipping glazes.

Soap Dispenser Tray

This was a bit of an experiment to see if I could make a kind of press mould by 3D printing it in two halves. You can see one half of the mold in the model below. Along with the soap dispensers that I was making it for.

Loading model...

The outcome of this was that it was a bit hard to have they clay be soft enough to deform into the mold while still having enough form to get it back out of the mold without severly deforming it. Some kind of mould release might have helped.

I’ve been putting of trying proper slipcasting where you pour liquid clay into a plaster mold and let it set. Using the 3d printed object to make a plaster mold then using that for slip casting would likely give much better results. Next time!